Overview

In today’s rapidly evolving manufacturing landscape, smart factories have become game-changers. They help businesses optimize processes and boost productivity. One key technology driving this transformation is Azure Digital Twins. This platform empowers manufacturers to create digital replicas of their physical environments. It supports real-time monitoring and advanced analytics. Ultimately, it improves operational efficiency.

What Is Azure Digital Twins?

Azure Digital Twins is a sophisticated platform that lets organizations build digital models of their physical assets. It mirrors real-world infrastructure and provides valuable insights into operations. The service offers real-time monitoring and predictive analytics. According to Microsoft, digital twins help manufacturers enhance productivity, reduce costs, and drive innovation.

Shifting to Proactive Management

Understanding this application is crucial for manufacturers. It shifts the paradigm from reactive to proactive management. With real-time data and simulations, businesses can optimize operations and respond swiftly to market changes. This positions them as leaders in the industry.

How to Use Azure Digital Twins in Smart Factory Development

Define the Scope

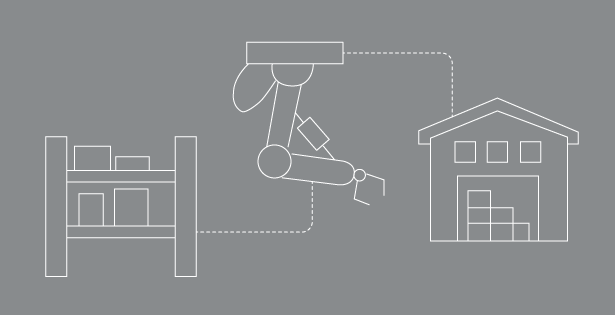

To use Azure Digital Twins effectively in smart factory development, start by defining the scope of your digital twin. Identify which elements of your factory you want to replicate and monitor—this could include individual machines, full production lines, or even supply chain logistics. Establishing clear objectives will guide how complex and detailed your digital twin needs to be.

Connect IoT Devices

Once the scope is clear, the next step is to connect IoT devices and sensors across your facility. These devices, embedded in equipment, collect real-time data that fuels the accuracy of your digital twin. Common sensor types include temperature monitors, motion detectors, and machine performance trackers.

Model Your Factory Digitally

After the IoT devices are in place and transmitting data, you can begin modeling your physical environment. The platform supports detailed 3D models or schematic layouts of machines and systems. These models are dynamic—continuously updated by the data collected—allowing manufacturers to monitor performance and visualize system behaviors in a safe, virtual space.

Enhance Your Digital Twin with AI and Analytics

Integrating advanced data analytics and artificial intelligence (AI) into your digital twin unlocks even more powerful capabilities. By analyzing real-time data, manufacturers can detect patterns and potential issues before they become major problems. Azure Digital Twins also supports simulations that let organizations explore different operational scenarios, enabling smarter decisions and greater efficiency.

Predict Equipment Issues Before They Happen

One of the most valuable applications of Azure Digital Twins is predictive maintenance. By analyzing data from IoT sensors and applying AI-generated insights, manufacturers can forecast equipment failures and schedule maintenance proactively. This reduces the chance of unexpected downtime and keeps operations running smoothly.

Optimize Processes Through Virtual Testing

Azure Digital Twins also supports continuous process optimization. Manufacturers can simulate workflow changes, test new configurations, and evaluate improvements—all before making changes in the real world. This ability to experiment virtually helps reduce risk, save resources, and improve overall factory performance.

Conclusion

Azure Digital Twins is revolutionizing the way manufacturers approach smart factory development. By creating digital replicas of physical assets, organizations can gain unprecedented control over their operations, minimize risks, and continuously optimize processes. The ability to simulate scenarios and predict future outcomes not only opens new avenues for efficiency but also positions manufacturers to thrive in an increasingly competitive landscape.

Are you ready to elevate your factory operations with Azure Digital Twins? Discover how this transformative technology can enhance your production environment by signing up for a free consultation or a live demo today by filling out the form below. Explore the opportunities for digital transformation that await your business and learn more here.

RSMUS.com

RSMUS.com