Why Secure IoT Matters in Manufacturing

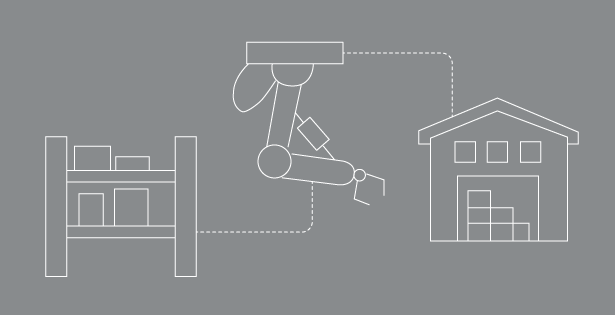

As manufacturers continue to adopt digital technologies, the need to secure IoT in manufacturing has never been more urgent. While IoT devices improve productivity and enable real-time monitoring, they also increase exposure to cyberattacks. A proactive security approach is essential to protect operations, data, and compliance across the digital factory.

Why It’s Critical to Secure IoT in Manufacturing

The Internet of Things (IoT) is transforming manufacturing by streamlining workflows and enabling predictive maintenance. However, this connectivity expands the attack surface, putting critical systems at risk. With 40% of cyberattacks in U.S. manufacturing caused by stolen credentials, the consequences of an insecure system can be severe—ransomware, supply chain disruption, and costly downtime.

To secure IoT in manufacturing, companies must protect sensitive data, defend against evolving threats, and comply with industry regulations.

Best Practices to Secure IoT in in Manufacturing

1. Implement Device Identity and Authentication

Each IoT device should have a unique identity and secure authentication. Azure IoT Hub supports per-device authentication using X.509 certificates or SAS tokens, preventing unauthorized access and credential misuse.

2. Ensure Endpoint Protection with Regular Updates

Firmware updates are critical, but many factory IoT devices can’t be easily patched. Azure IoT Hub enables over-the-air (OTA) firmware updates. For legacy devices, implement asset discovery tools and Zero Trust network architectures to monitor and protect vulnerable endpoints.

3. Use End-to-End Encryption

Encrypt data in transit and at rest using Transport Layer Security (TLS). Azure IoT Hub offers these protections, and private 5G networks can enhance security by minimizing Wi-Fi-based vulnerabilities.

4. Monitor Threats with Azure Security Center

Continuous, real-time threat detection is key. Azure Security Center for IoT uses machine learning and AI to spot unusual patterns and alert teams to potential breaches—enabling fast response and resolution.

5. Control Access with Role-Based Access Control (RBAC)

Azure IoT Hub integrates with Azure Active Directory (AAD), allowing for role-based access control. Assign the minimum required access to each user to minimize insider threats and prevent accidental exposure.

6. Strengthen Network Security

Deploy firewalls, intrusion detection systems (IDS), and virtual private networks (VPNs) within your Azure environment. Consider using Citizens Broadband Radio Service (CBRS) for private 5G networks to further secure internal traffic.

7. Automate Threat Remediation and Maintain Compliance

Automated threat remediation—like patch deployment and traffic blocking—reduces risk. Azure Policy ensures compliance with standards like ISO 27001 and NIST 800-53, applying security policies consistently across your IoT landscape.

Additional Tips for IoT Security Success

-

Adopt Zero Trust Principles: Assume no device or user is trustworthy by default. This enforces strong verification at every access point.

-

Invest in Training: Cybersecurity talent gaps can compromise your systems. Upskill staff or consider managed security services.

-

Avoid Shadow IT: Discourage the use of unsanctioned devices and software, which can introduce major security vulnerabilities.

Conclusion

Securing IoT in manufacturing requires a layered, proactive approach. Azure IoT provides the tools to manage identities, encrypt data, monitor threats, and ensure compliance—helping manufacturers stay secure in an increasingly connected world.

Ready to protect your factory? Contact us to learn how Azure IoT can help you build a secure digital manufacturing environment.

RSMUS.com

RSMUS.com