The manufacturing sector is increasingly relying on data to drive efficiency, optimize processes and gain a competitive edge. However, while data has the potential to transform manufacturing operations, many companies face challenges in managing and using this data effectively. Below, we’ll explore the top five data challenges that manufacturing companies encounter and how they can be addressed to unlock the true value of data.

1. Integrating data from multiple sources

The challenge:

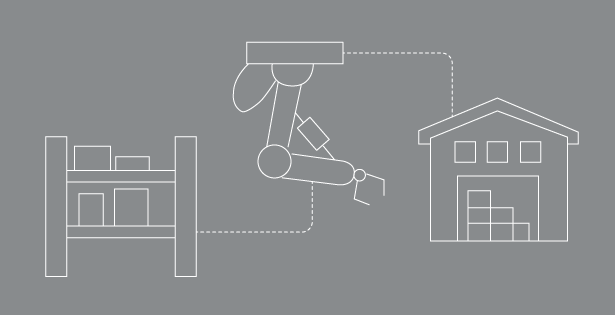

In manufacturing environments, data is often spread across various systems such as customer relationship management, enterprise resource planning, machinery sensors and supply chain management tools. When data resides in different systems, gaining a unified view of business performance can be difficult. This fragmentation leads to inefficiencies and hinders the ability to make informed, data-driven decisions.

The solution:

A centralized data warehouse is key to overcoming this challenge. Data warehousing enables the integration of information from multiple sources into a cohesive system. This approach not only streamlines reporting but also ensures that data from different systems is consistent and accessible. Data warehousing enforces standard business logic and data quality controls on the data so that data prepared for reports is consistent and accurate. Building a data warehouse requires defining data models that can handle large data volumes while ensuring data accuracy. By consolidating data into a single source of truth, manufacturing companies can easily access the insights they need to make strategic decisions and optimize operations.

2. Ensuring data quality and accuracy

The challenge:

Data quality issues are common in the manufacturing sector due to legacy systems, human error and complex processes. Inaccurate, inconsistent or incomplete data can lead to mistrust in reporting and analytics and data-driven, decision making processes. Data is at the root of innovation and business success. If business leaders cannot rely on the data they have, implementing effective strategies and driving growth becomes difficult.

The solution:

A robust data quality assessment, including data profiling, is the first step in identifying and addressing this issue. This assessment involves evaluating data from source systems for accuracy, completeness and consistency. After identifying any data quality issues, the business should determine the associated impact of poor data quality and prioritize issues for remediation. These remediation efforts may vary from implementing data validation processes, establishing regular data cleansing processes and enforcing quality checks within the data warehouse. To sustain the quality of information, a data governance strategy and framework can enable accountability and efficient processes, so companies can trust their data for strategic decision making.

3. Manual reporting and inconsistent results

The challenge:

Manual reporting is time-consuming and error-prone. In many manufacturing companies, employees spend hours compiling reports in spreadsheets, which often leads to inconsistent results. Multiple versions of the same report can exist, each with slightly different numbers depending on how data was pulled or calculated. This inconsistency not only wastes time but also undermines confidence in the data.

The solution:

Automating the reporting process through business intelligence (BI) tools can drastically reduce the time spent on manual tasks while improving data accuracy. By leveraging a centralized data warehouse, BI tools can generate real-time reports and dashboards tailored to specific business needs. These tools allow companies to easily monitor key performance indicators and gain immediate access to critical insights, supporting faster and more informed decision making. Automation also ensures that reports are consistent across the organization, providing a single source of truth for all stakeholders.

4. Addressing data silos and lack of a single source of truth

The challenge:

Data silos occur when data is stored in separate systems or departments, making it difficult to access and share information. This fragmentation leads to inefficiencies and prevents companies from having a holistic view of their operations. Without a single source of truth, decision-making becomes a guessing game based on incomplete or outdated information.

The solution:

Implementing a comprehensive data strategy is crucial for eliminating data silos and establishing a unified source of truth. A data strategy involves defining how data is collected, stored, integrated and accessed across the organization. By creating a centralized data warehouse that consolidates information from various sources, companies can ensure that their data is accurate, up-to-date and easily accessible. This centralized approach not only streamlines reporting but also supports advanced analytics, providing deeper insights into business performance and market trends.

5. Leveraging advanced analytics to drive business growth

The challenge:

While many manufacturing companies collect vast amounts of data, they often struggle to leverage it for actionable insights. Advanced analytics, including predictive and prescriptive analytics, can provide a competitive edge by uncovering patterns, trends and opportunities for growth. However, implementing advanced analytics requires the right tools, experience and data infrastructure.

The solution:

To make the most of advanced analytics, companies need to develop a data strategy that includes the integration of AI and machine learning tools. These technologies can analyze large datasets, identify trends and make predictions that support strategic decision making. For example, predictive analytics can be used to forecast equipment maintenance needs, optimize supply chain operations and anticipate market demand. By implementing AI-driven solutions, manufacturing companies can automate repetitive tasks, improve customer segmentation and mitigate potential business risks. Investing in advanced analytics capabilities empowers companies to not only understand their current operations but also to anticipate future challenges and opportunities.

The takeaway

Data holds immense potential to transform manufacturing operations, driving efficiency, improving product quality and supporting strategic decision making. However, many manufacturing companies face challenges in managing their data effectively, from integrating data across multiple sources to ensuring data quality and accuracy. By adopting a comprehensive data strategy, implementing centralized data warehousing and leveraging advanced analytics, manufacturing companies can overcome these challenges and unlock the full value of their data.

Addressing data-related issues is not just about solving immediate problems; it’s about building a data-driven culture that supports long-term growth and innovation. With the right data strategy and tools, manufacturing companies can confidently make informed decisions, optimize processes and stay ahead in a rapidly evolving market.

RSMUS.com

RSMUS.com