In today’s manufacturing environment, products need to be managed for improvements and issue resolution in an efficient and effective process. Consumers of industrial products are increasingly looking for manufacturers to increase quality, reliability, and safety products. Manufacturers need a solution to react to changes in their environment while also effectively managing cost, reducing waste during design changes, reducing production errors, and controlling the introduction of new and changed products.

The engineering change management module within Dynamics 365 for Supply Chain allows companies to take control of a product’s lifecycle. Features which will be delved into this series include lifecycle management, change management, change orders, item creation workflow/readiness checks, and product release policies. The key feature of engineering change management is the ability to create product versioning.

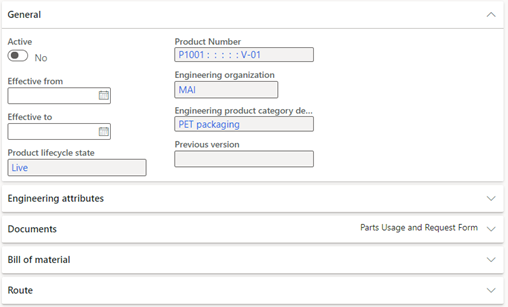

Product versioning, while not required to utilize all features of engineering change management, is the center piece of the solution. The ability to create multiple versions of a product allows companies to manage inventory, bill of materials, and attributes of various iterations of products. Versioning products will allow manufacturers to control defective versions versus improvements to new products. Defective products will be deactivated immediately while improvements to products will keep older versions active until existing inventory is depleted.

Version: Active vs Inactive

While product versioning is not mandatory to utilize the majority of engineering change management functionality, it allows companies to effectively manage changing product needs.

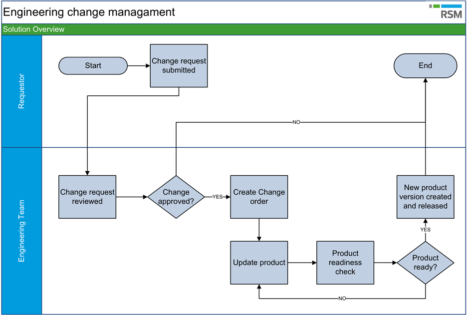

A regimented change management process within product development is important to manufacturers as it gives workers the tools to act on changes necessary when defects or improvements are identified during the product lifecycle. The process alerts workers when they need to act and how long they have to take action based on priority and severity of the change needed. A good change management process gives your front-line workers (customer service, production, sales) the power to identify when changes are needed and create the necessary change requests directly in the system.

Example of a product lifecycle with change management:

To turn on Engineering Change Management in Dynamics 365 for Finance and Supply Chain you will first need to turn on the license configuration.

- Place environment in “Maintenance Mode”

- Navigate to System Administration > Setup > License Configuration

- Navigate to Trade > Engineering Change Management and turn on functionality

- Includes Attribute search and Change management for process manufacturing

- Navigate to Trade > Product dimension – Version and turn on functionality

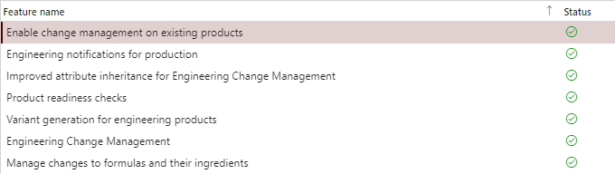

- Navigate to Feature Management

- Enable the following features.

More features will be added and in future posts we will go through the various functionalities within engineering change management and how it can be used both with and without the overall engineering change management module.

RSMUS.com

RSMUS.com