Do legacy inventory problems plague your system? Would you like to correct the inventory quantity and valuations mismatches?

Overtime as you use your system, and update your supply chain processes (learning curve of the system and creating your standard operating procedures), you might not notice inventory quantities or values that needs to be fixed. If they are not corrected, the legacy issues will persist and slow down the process of making changes to your system. An example of a system change could be changing of costing methodology for your company. These inventory quantity or value mismatches can be created from all sorts of ways.

The mismatch of quantities and/or values may be caused by any of the following:

- System process change due to your company changing its process or methodology. An example is going from Work Order process to only Assembly Build process.

- If bins are on and a transaction has yet to be assigned to a specific bin or if the bin has quantity on hand but the bin on the item record has been removed. This is due to a process change.

- In-activating items that still have inventory and/or values depending on their costing method. An example of this is going from FIFO costing to Standard costing.

- Inventory quantity in the Bin Putaway Worksheet at a location has not been put away. This is due to a process change.

Instead of tracking back to where the issues might have happened (this could be transactions from years ago that are in closed periods), there are two ways to fix the issue. Adjust Inventory Worksheet is the best and fastest way to fix the issue.

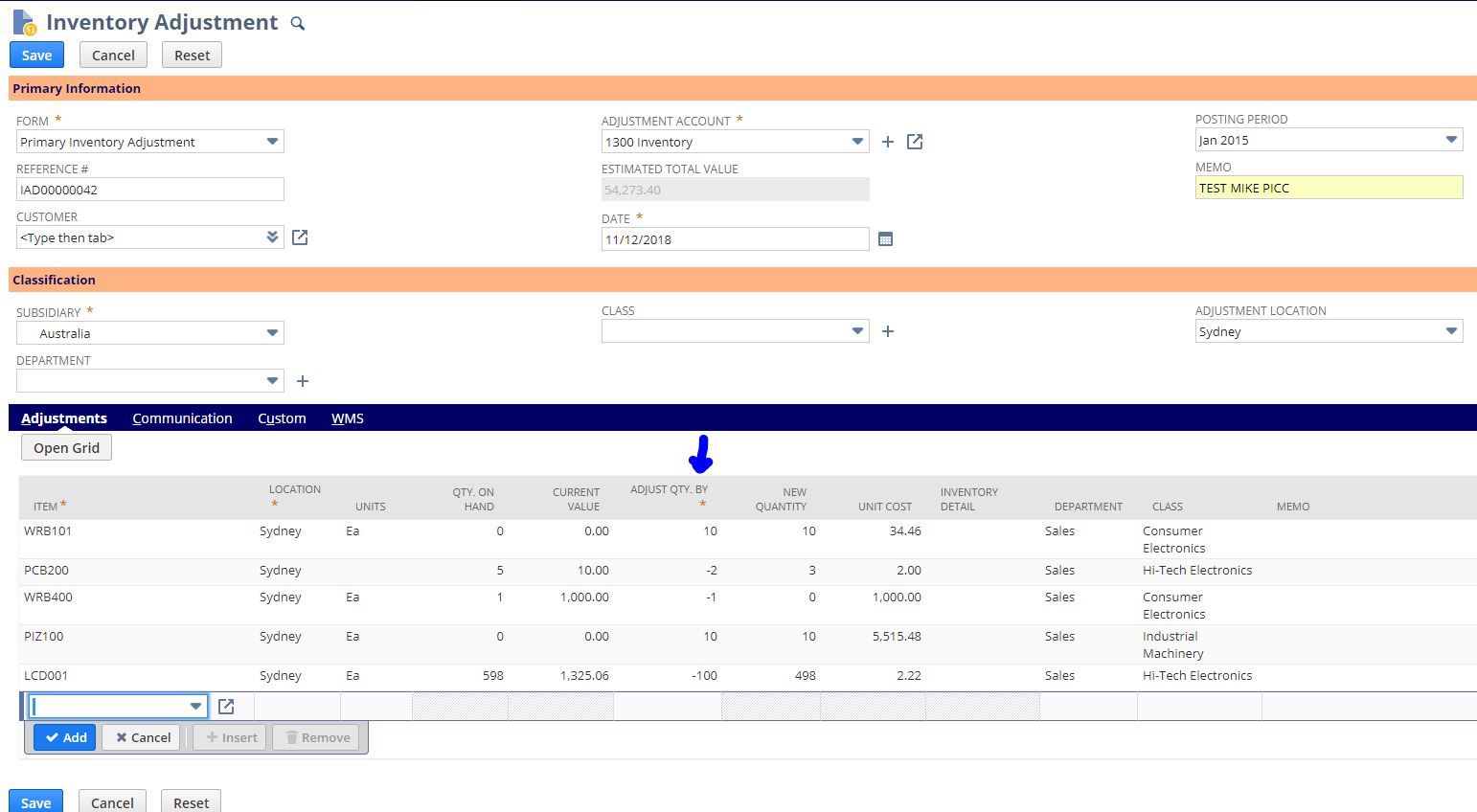

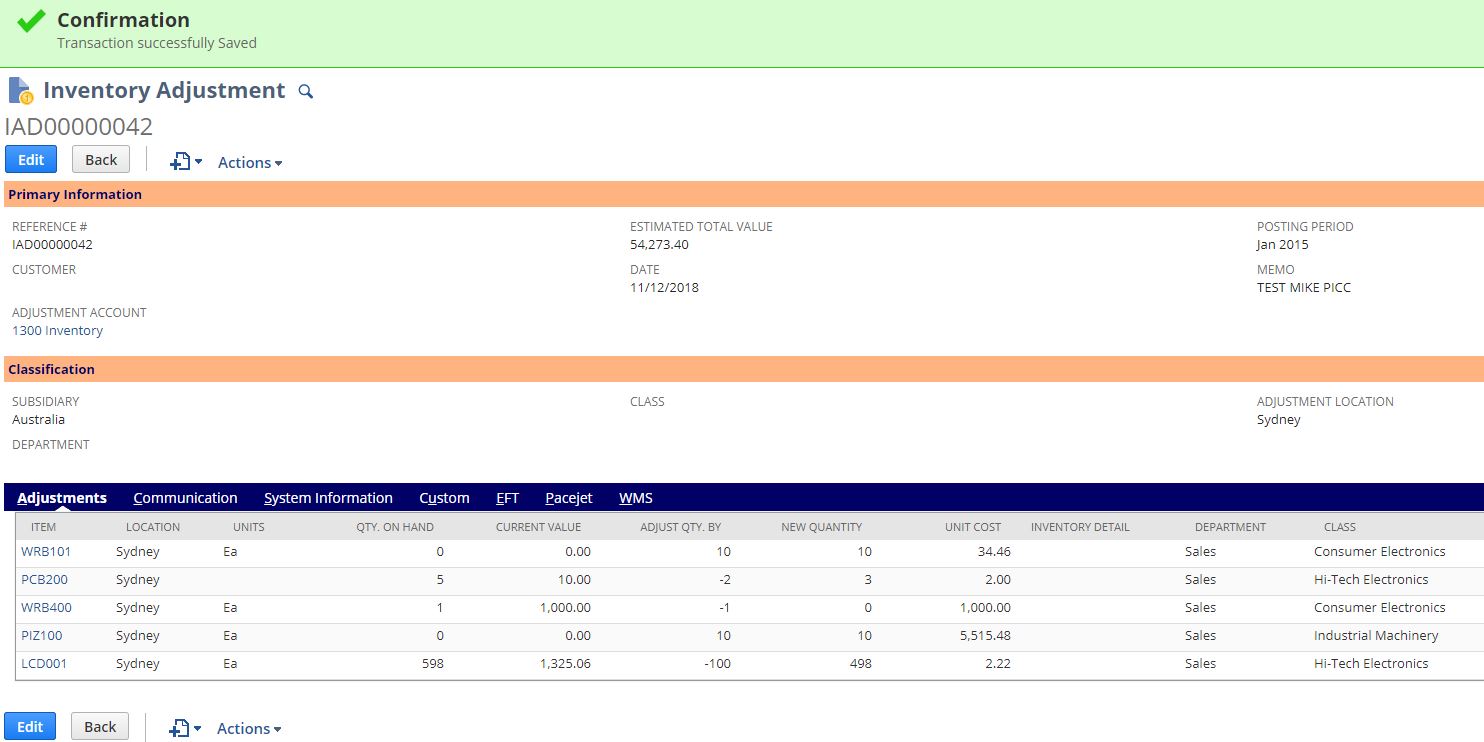

Adjusting Inventory:

Create an Inventory Adjustment for that item (or items) that has the mismatch. Follow the path: Transactions –> Inventory –> Adjust Inventory. Below you can see you are only able to change the adjust by quantities of the items to make the new quantities appear. The values of items (unit cost) are pulling in from the system automatically. You cannot change the item value in an inventory adjustment, as this is a limitation of this feature.

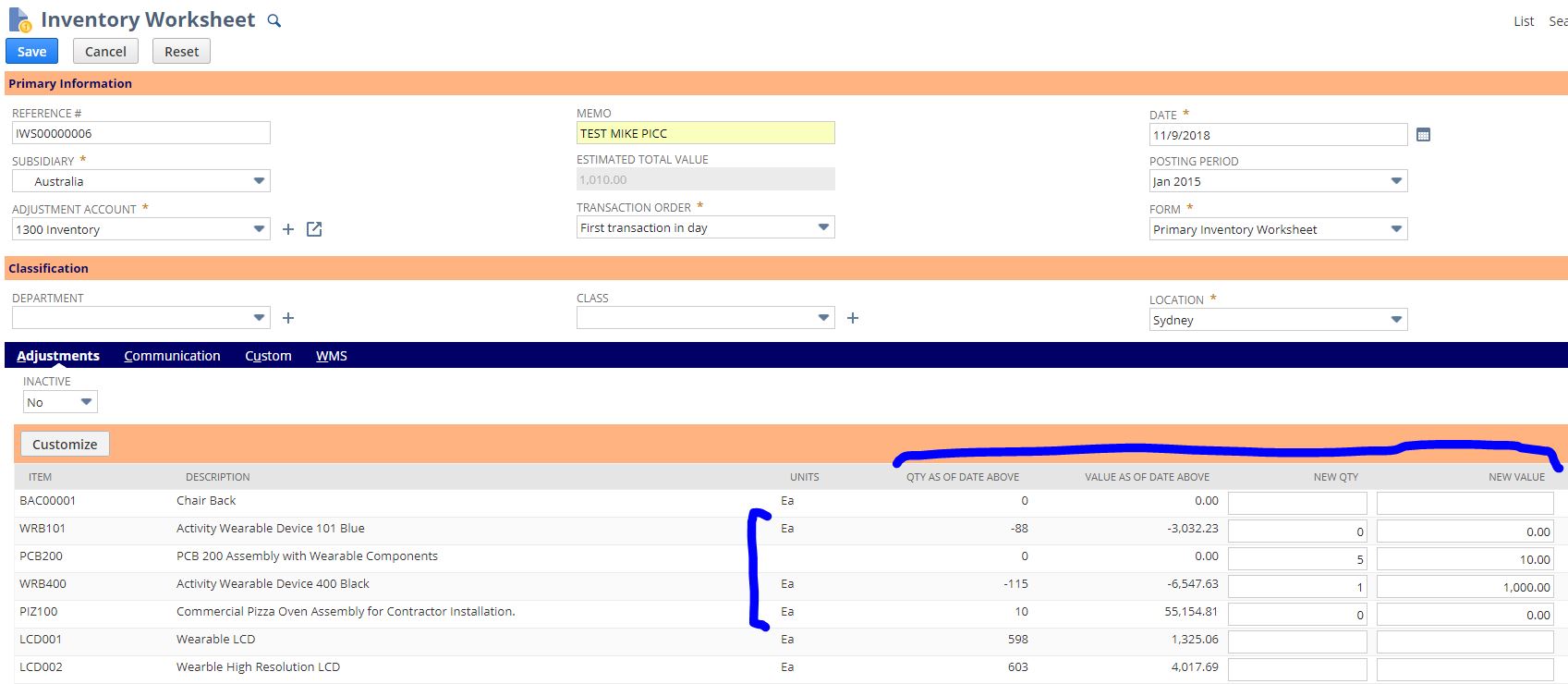

Adjust Inventory Worksheet:

Create an Inventory Adjustment Worksheet for that item (or items) that has the mismatch. Follow the path: Transactions –> Inventory –> Adjust Inventory Worksheet. Below you can see you are able to change the quantities and values of 4 items. This will be a hard set adjustment of the values you plug-in with no system calculation.

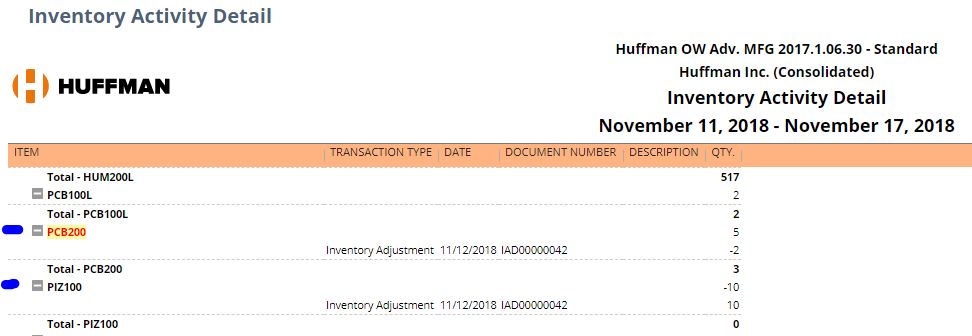

By running the Inventory Activity Detail report and Inventory Valuation report, you can see the changes in the item quantities and values that you made.

Inventory Activity Detail Report:

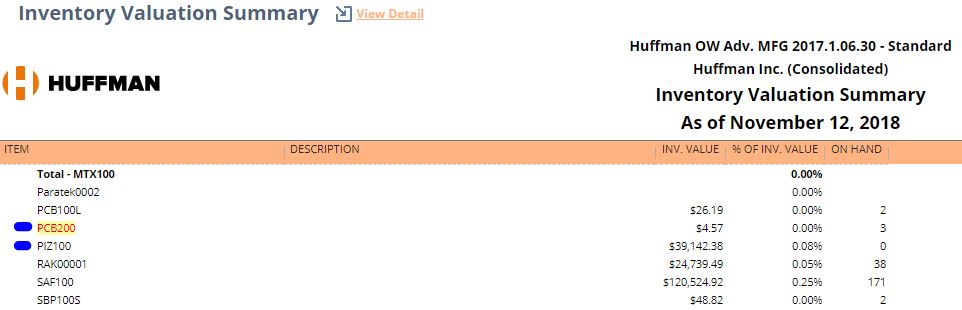

Inventory Valuation Report:

In conclusion, if you are reviewing (and fixing) on a routine basis (every week, month, etc.) before a period close, using the Inventory Adjustment is your best option. If you are fixing an issue in a closed period, I would use the Inventory Worksheet. Either way, you will be able to correct any inventory quantity or valuation mismatch error you find.

RSMUS.com

RSMUS.com