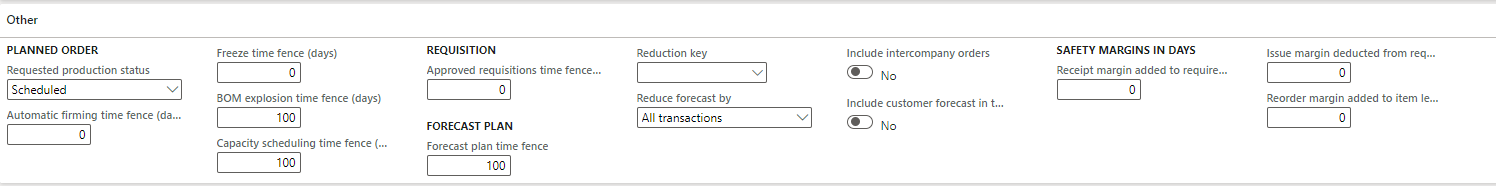

Last month we discussed the coverage groups in Master planning and went through its General tab. In this article, we will go over the Other FastTab.

Master planning > Setup > Coverage > Coverage groups

In the Other FastTab, the first group regards a Planned Order. You are asked to select the Requested production order status. The drop-down list can be confusing since it includes all production order statuses, but all will return an error except for Scheduled, Released, or Started. If Master planning is run and a production order is, for example, Scheduled, that order can be automatically firmed and created in the number of days listed.

The Freeze time fence indicates how many days an existing planned order would not be changed when Master planning is run again.

The BOM explosion time fence is when planned orders for BOM items are exploded into requirements for components. Example: an entry of 60 days means that any planned order within 60 days will be exploded into its components. If it is more than 60 days, they are not exploded.

The Capacity time fence is when the planned production order is capacity-scheduled using the items route and plans the route based on the requirement date.

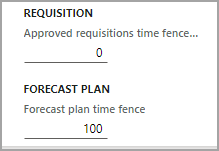

The Approved requisition time fence is based on if you set up Master planning to create planned orders for requisition demand. If set to yes, this setting would override the approved requisitions time fence that is defined during master scheduling. An example would be if you specify that only unfulfilled, past-due demand from requisitions that were created in the last 10 days should be considered.

The Forecast plan time fence is when the demand from the forecast plan is included in master scheduling. If you enter 100 days, it means you will look at the forecast for the next 100 days and include requirements during that time.

The Reduction key is a pre-set identifier that applies a percentage to either reduce or increase the forecast. For example, if you have a forecast for 50,000 items to be sold in August, but something unexpected to lower it to 40,000, you do not have to change the forecast, just change the reduction key to lower the forecast by 20%.

Below that, there is an option to Reduce forecast by either Orders or All transactions. This means that if there are transactions posted, the forecasted numbers will be reduced.

The coverage group then allows you to select if you want to Include intercompany transactions and Include customer forecast in the demand forecast.

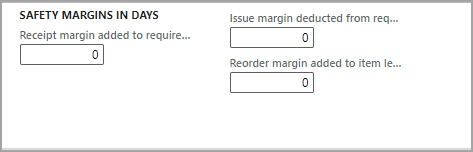

The final section in this FastTab is the Safety Margins in Days. Safety margins, expressed in Receipt margin, Issue margin, and Reorder margin. Margins work like this:

- If a receipt margin is three days and a purchase order is scheduled the receipt is set for May 2 and you’re planning to receive it on May 5. Causes for this could be that it would take three days to fully document and record the receipt, or perhaps the vendor is consistently late so you need to plan an extra three days.

- The issue margin is subtracted from the requirement date. For example, if a sales order is scheduled for delivery on May 6 with a three-day margin, the adjusted delivery date would be May 3. It would take the customer an extra three days to receive and get the items ready to sell on the May 6 requirement date.

- The reorder margin is added to the lead time for planned orders. This is in days and means that it takes three additional days, perhaps for approvals, to get to the point of placing the order.

In our next article, we will address the final two tabs on the Coverage groups form.

Want to learn more about Dynamics 365 for Finance and Operations? Visit academy.rsmus.com for eLearning courses.

RSMUS.com

RSMUS.com