For those of you involved in running Master planning in Dynamics 365 Supply Chain Management, you know the drill: schedule it to run after normal working hours, plan for it run for 3-4 hours, and take any actions that are needed at the beginning of the next day.

Not only is this a drain of resources during the off-hours, but the results of the plan can be outdated based on transactions that happen early in the working day. While you may have learned how to deal with this, the good news is you don’t have to.

Planning Optimization is an add-in that eliminates these issues and meets the following goals:

- Shorter runtimes to improve performance

- Less impact on other processes while running master planning

- Run more frequent plans

Planning Optimization also provides other enhancements such as real-time insight into requirement changes on the supply side and how it affects existing orders.

So how does all this happen?

First, Planning Optimization is a service, separate from the SQL database that houses your data, and the existing Master planning system. Once it is installed on a Tier 2 environment and activated within the client, the system goes through the following steps:

- A request to run a plan is sent by Supply Chain Management

- Planning Optimization requests the service from the connecting add-in

z - The SQL database sends all the information about setup, plan, and transactional data to Planning Optimization and the connector translates the information between the client and the Planning optimization service

- Planning Optimization service does the calculations

- Planning results are sent back to Supply Chain Management, including planned orders, pegging information, messages, and warnings.

How to install the add-in from Lifecycle Services (LCS) and activate it in Supply Chain Management

- Once in your LCS Tier 2 environment, go to Full details

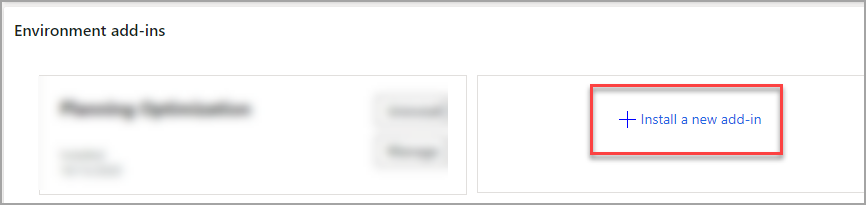

- In Environment add-ins, select Install a new add-in

- Select Planning Optimization

- On the next screen, select the box to agree to the terms and conditions, and then select Install.

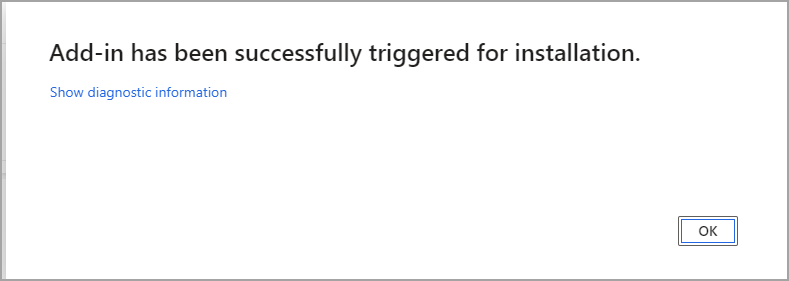

- You will get the screen below, and select OK

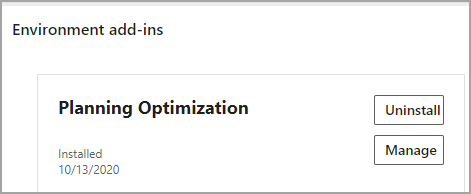

- Once your add-in is installed, you will see this screen.

- Now, go into Supply Chain Management

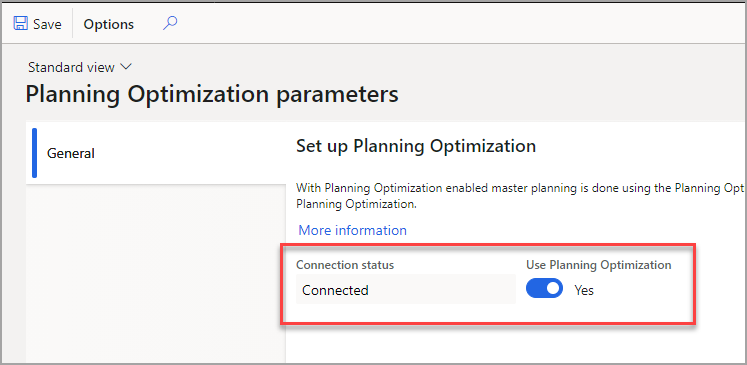

- Go to Master planning > Setup > Planning Optimization parameters

- The Connection status will show Connected after the add-in is installed.

- On the slider for Use Planning Optimization, set it to Yes

Functional features of Planning Optimization

In addition to the performance improvements from the add-in, there are functional features that are available when using Planning Optimization:

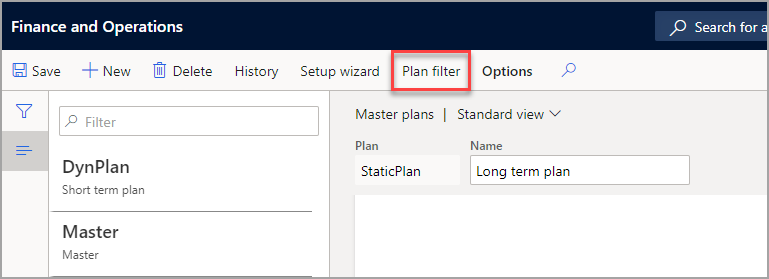

- Plan filters – this is helpful when creating plans that run frequently. The plan itself can have filters set up so that you don’t have to set the filter when running the plan. These filters are used in conjunction with filters you may apply when running the plan. Examples:

- If you have a Plan filter for items A, B, and C and your runtime filter is for item D, no items are planned since D is not a part of the Plan filter. The runtime filter must intersect with the Plan filter for there to be results

- With the same Plan filter (A, B, and C) a runtime filter for B is added. The only results will be for item B only.

Master planning > Setup > Plans > Master plans

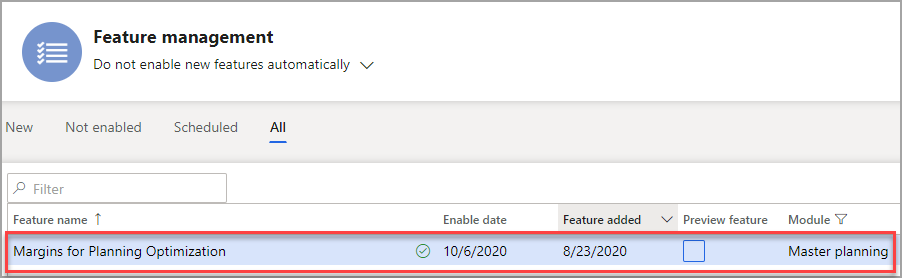

- Safety margins – all margins are defined in days and represent a kind of “buffer” zone, a time to add to the expected lead time to account for any needed time for administration, testing, etc. There are receipt margins, reorder margins, and issue margins that when applied in Planning Optimization, all three of these margins will affect the requirement date of the planned order.

- This feature must be turned on in Feature management as shown below:

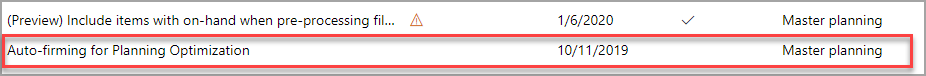

- Auto-firming of planned orders – Auto-firming is the process of releasing a planned order and converting it into a purchase order, a transfer, or a production order. With Planning Optimization, planned orders can be firmed during a plan run when the date is within the time fence for firming. This is another feature to be enabled in Feature management

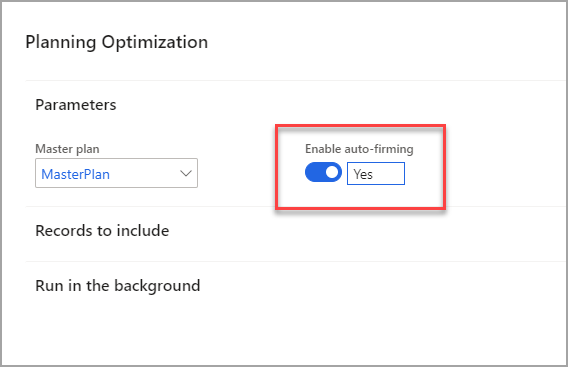

- When running a plan with Planning Optimization, this feature can be selected

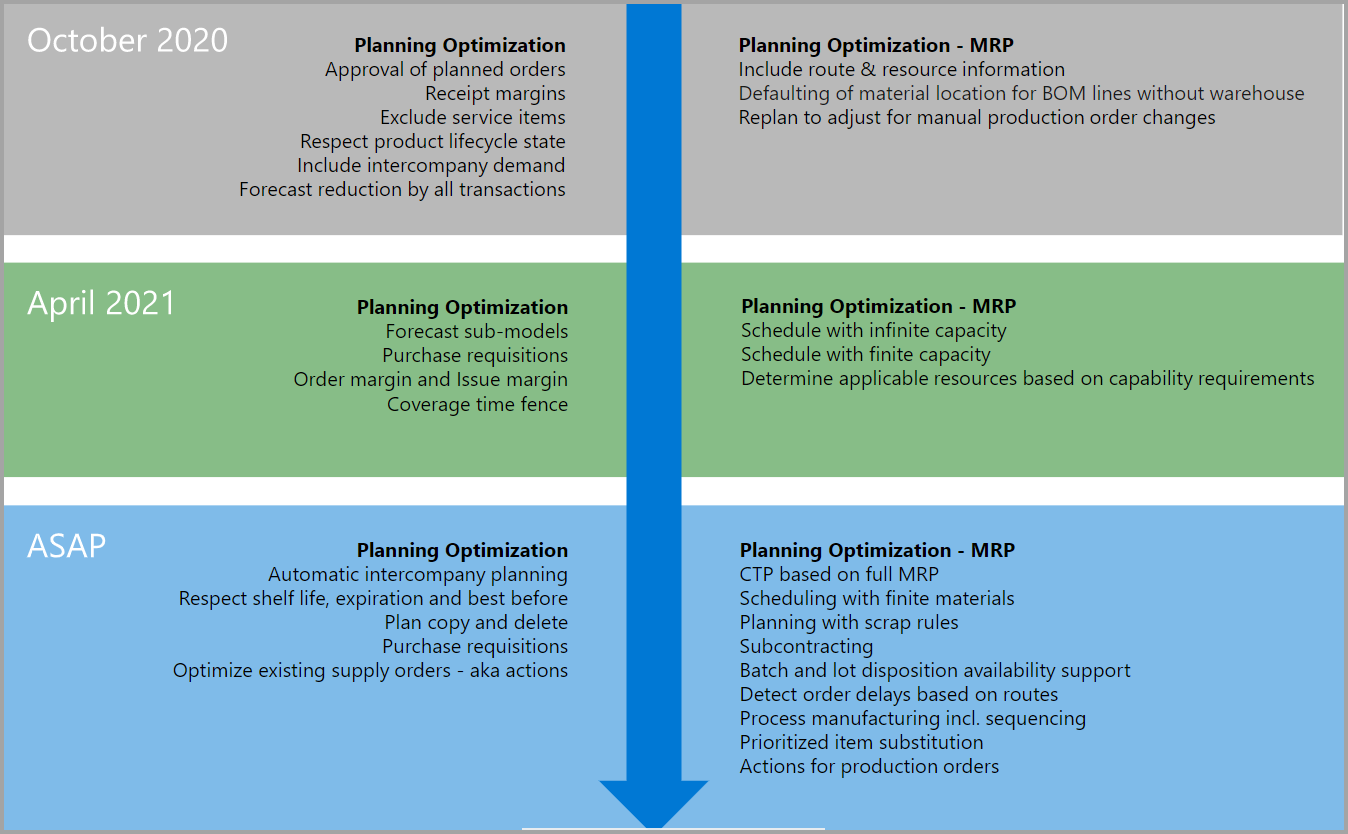

Eventually, the current master planning engine will be replaced by Planning Optimization. Only customers with on-premises deployments of Dynamics 365 Supply Chain Management may continue to use the current engine. Deprecation of distribution scenarios will start in April 2021 and in October 2021, the first MRP scenarios will begin to deprecate.

Here is a graphic of the features still to come in Planning Optimization and those that are available now:

Want to learn more about Dynamics 365? Visit academy.rsmus.com.

RSMUS.com

RSMUS.com