Introduction

With the NetSuite 2023.2 Release, a new and significant Lot sizing option has been introduced in Supply Planning – Minimum Order Quantity (MOQ). In this article, we will explore the necessity of this new option for Lot sizing and demonstrate how to utilize it with an example.

What is Minimum Order Quantity (MOQ)

In NetSuite’s supply planning feature, establishing a minimum order quantity for lot sizing helps optimize inventory management by ensuring that orders meet specific quantity thresholds. This approach reduces the expenses associated with handling and processing smaller orders and contributes to streamlining the supply chain process.

Minimum Order Quantity (MOQ) refers to the minimum amount of a product that a supplier or manufacturer is willing to sell to a buyer. It is commonly used in business-to-business (B2B) transactions, particularly in wholesale and manufacturing industries

What are the Lot sizing options in NetSuite

In Netsuite we have the following Lot Sizing options: –

Lot For Lot – proposes procurement orders based on daily projections.

Fixed Lot Size – a lot size that consistently uses the same quantity for a reorder. While the timing of the order may vary, the size of the order remains constant. This option might lead to multiple supply orders of the same size for the same date.

Fixed Lot Multiple – a lot size that always utilizes a multiple of a specific quantity for a reorder. Opting for this choice results in a single supply order.

Minimum Order Quantity (MOQ)– a lot size that always necessitates a minimum quantity to be ordered. After meeting the minimum quantity, the total required quantity will be the order quantity.

Periods of Supply – generates aggregated purchase orders or work orders based on the overall demand requirements over a designated period, such as weekly or monthly.

Minimum Order Quantity (MOQ)

A Minimum Order Quantity will be necessary for new planned orders generated by the planning engine. If you require a larger quantity, you can add the necessary amount to meet the minimum quantity.

Here is how it functions:

- Define Minimum Order Quantity: Determine the minimum quantity required for each item. This quantity may vary based on factors such as production capacity, supplier requirements, or economic order quantity (EOQ) calculations.

- Setup Items with MOQ per location: Once the minimum order quantity rule is configured, apply it to relevant items in your inventory. You may want to apply different minimum order quantities based on item characteristics such as demand patterns, value, or storage constraints.

- Review and Adjust: Regularly review and adjust your lot sizing rules based on changing business needs, inventory performance, and supplier conditions. Flexibility is essential for optimizing inventory management over time.

- Setup the Supply Planning to Include these items: Ensure these items are included in the supply planning setup and processed for supply plan creation.

*Supply Lot Sizing Method cannot be Minimum Order Quantity when Replenishment Method is Time Phased.

Pre-requisites: –

1. Account has MATERIAL REQUIREMENTS PLANNING enabled.

2. All MRP related setup is configured, and the item is included in the Supply Plan Definition.

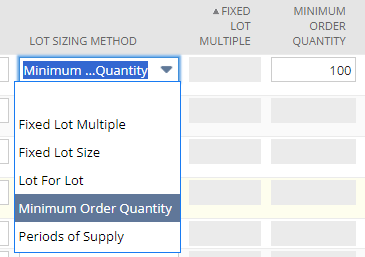

Setup:Item Location Configuration, Separate Lot Sizing options will be provided for Minimum Order Quantity.

1.

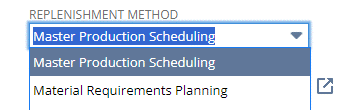

MOQ is available only when the REPLENISHMENT METHOD, on the item record, is set to Material Requirements Planning or Master Production Scheduling.

2. Item Location Configuration

In the Item Location Configuration set the Lot Sizing Method as Minimum Order Quantity, and the enter the Minimum Order Quantity value. See below image for reference.

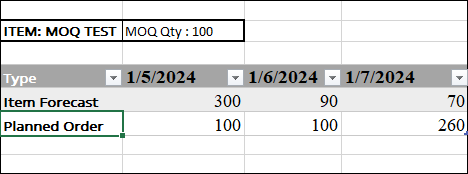

Example: Let us consider the below example to better our understanding related to MOQ

Demand:

1. Demand 1 – 300

2. Demand 2 – 90

3. Demand 3 – 70

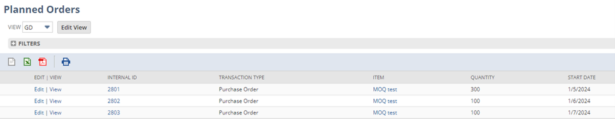

Planned Purchase Orders:

1. When utilizing the Minimum Order Quantity option, planned purchase orders will display a quantity greater than the minimum order quantity when the required quantity exceeds the minimum order quantity. In the example, please review below mentioned order for the demand of 300 quantity.

a. The Purchase Order Internal ID: 2801 was proposed for the Demand 1 of 300 quantity as it is greater than the MOQ set at 100.

2. The quantity will be equal to the minimum order quantity when the required quantity is less than or equal to the minimum order quantity. In the example, please review below mentioned orders. Even though the demand was for lesser quantity the planned order was created for MOQ: 100 quantity.

a. The Purchase Order Internal ID: 2802 was proposed for the Demand 2 of 90 quantity.

b. The Purchase Order Internal ID: 2803 was proposed for the Demand 3 of 70 quantity.

Closing

Minimum Order Quantity (MOQ) is a valuable addition to NetSuite’s supply planning feature, addressing the crucial aspect of lot sizing that was previously lacking. This enhancement demonstrates how NetSuite continually evolves and updates with beneficial feature releases to help customers achieve their full potential.

For further details, discussions, or demonstrations, please contact the author using the details mentioned in the link: Gaurav Dighe.

RSMUS.com

RSMUS.com