NetSuite’s Outsourced Manufacturing function allows companies to track production of finished goods performed by outside companies. Outsourced Manufacturing (also referred to as Contract Manufacturing) is the process where company owned components or raw materials are sent to a vendor facility and assembled at that location.

This article explains the process of Outsourced Manufacturing starting from the Purchase Order or Work Order. For a broader overview of the Contract Manufacturing process within NetSuite, navigate to RSM’s Blog article here:

Outsourced Manufacturing Configuration

Quick Configuration Steps/Required Features to Enable:

- Purchase Orders

- Advanced Receiving

- Multi-Location Inventory

- Assembly Items

- Advanced Bill of Materials

- Work Orders

Once the above features are enabled, the Outsourced Manufacturing feature can be enabled:

- Setup > Company > Enable Features > Items and Inventory > Enable Outsourced Manufacturing

Additional Set-up Tasks:

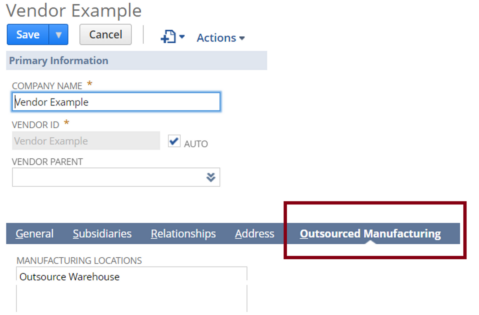

- Create an Outsourced Manufacturing Location (choose an intuitive name like “Outsourced Warehouse”)

- Configure a Vendor to link the Outsourced Location(s) to the Vendor Record

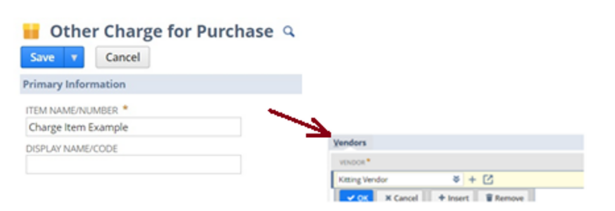

- Create an Other Charge for Purchase Item to represent the vendor’s outsourcing charge (example: Outsource Charge Item). Associate the item with the vendor under the “Vendors” subtab.

- Set the “Can Be Fulfilled/Received” checkbox under Preferences to “TRUE” for the Outsource Charge item so the item can be fulfilled directly from the Outsourced location.

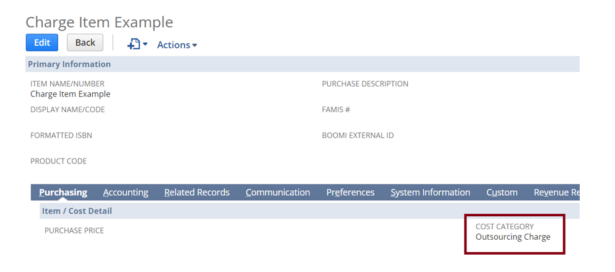

- Set the Cost Category to “Outsourcing Charge”.

Bill of Materials/Revision Configuration Steps:

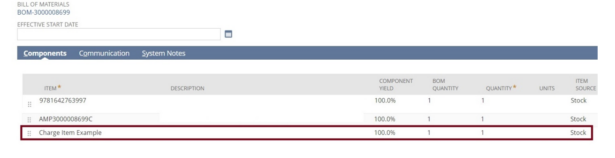

- Configure an Assembly Item and corresponding Bill of Material and Revision(s).

- Add the Outsource Charge item to the Revision record.

Inventory Requirement:

In order to build assemblies you need adequate inventory for each component that makes up the assemblies. That means you have to get the inventory to the outsource location.

Some Options:

- place a purchase order with a supplier and ship to the outsource location

- create a transfer order from a stocking location to the outsource location

- create an inventory transfer from a stocking location to the outsource location

- create an inventory adjustment and add the necessary quantities to the outsource location

Outsourced Manufacturing Flow from the Purchase Order

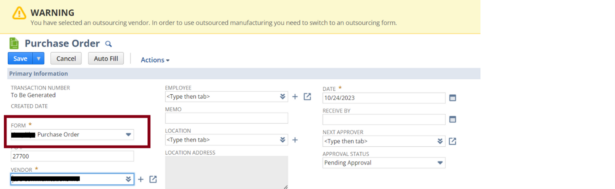

- Navigate to Transactions > Purchases > Enter Purchase Orders > New

- Select an Outsourcing Vendor

- A warning message will appear instructing you to change the PO form to an Outsourced Purchase Order form. Select the Outsourced PO form.

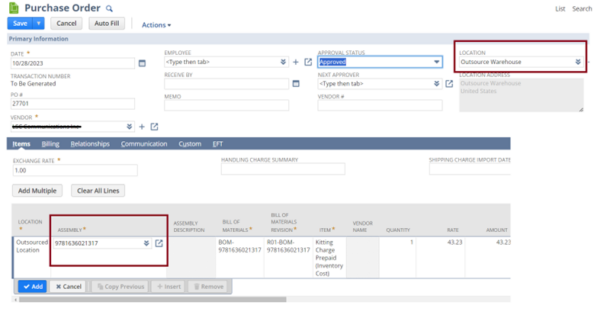

- Select the Outsourced Location in the LOCATION header field.

- Add the Assembly (or Assemblies) to be built to the PO line(s)

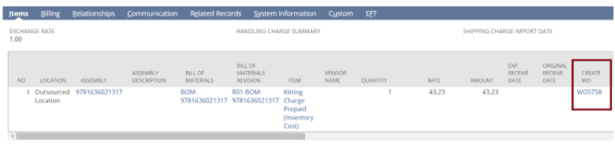

- Upon saving the Purchase Order, the Outsourced WO is automatically created.

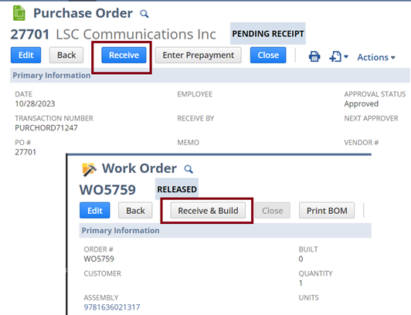

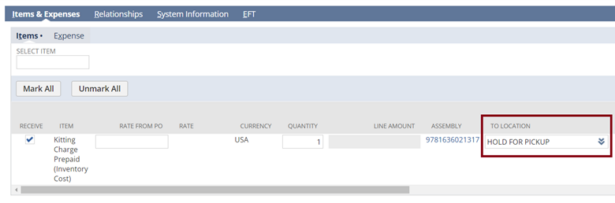

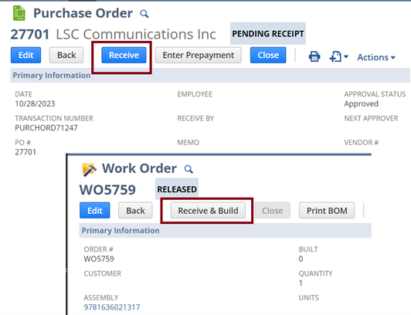

- Select “Receive” on the Purchase Order, OR select “Receive & Build” on the Work Order to complete the Assembly Build:

- During the receiving process, you can change the receiving location to a different location: this automatically generates an Inventory Transfer of the completed assembly to the desired location:

- Press the “Bill” button on the Outsourced PO to enter the Vendor Bill for the Outsourcing Charge item.

Outsourced Manufacturing Flow from the Work Order

Why would you initiate Outsource Manufacturing from the Work Order?

- Item Supply Plans (using Master Production Scheduling, Material Requirements Planning, or Reorder Point) allow bulk creation of Work Orders using the Mass Create Work Orders screen.

- A clients’ sales process may require entering a Sales Order where the sales order line creates an Outsourced Work Order.

- Warehouse teams may prefer to create Work Orders rather than Purchase Orders

Outsourced Manufacturing Flow from the Enter Work Orders screen:

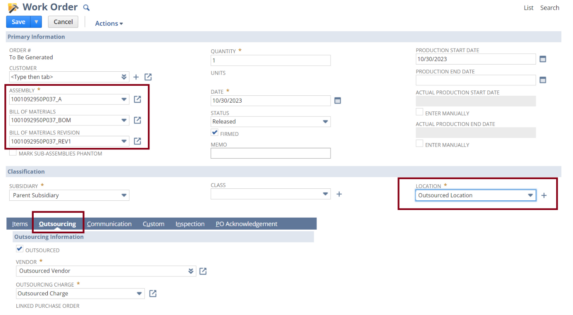

- Navigate to Transactions > Manufacturing > Enter Work Orders

- Set the Subsidiary and Location

- Select an Assembly and enter the desired quantity

- Select the BOM and BOM Revision (as needed)

- Depending on the BOM configuration, check the Outsourced checkbox, set an Outsourced Vendor, and Outsourcing Charge under the Outsourcing subtab.

- Press SAVE.

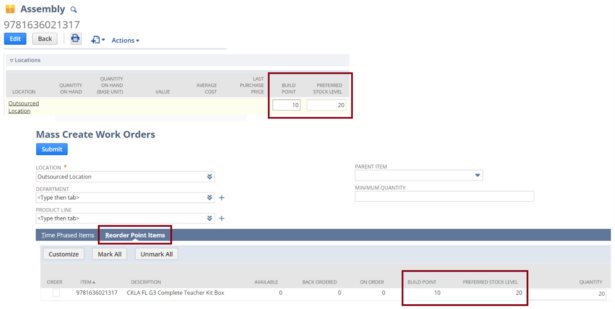

Outsourced Manufacturing Flow from the Mass Create Work Orders screen:

- Navigate to Transactions > Manufacturing > Mass Create Work Orders

- Click the Time Phased, Reorder Point Items or Planned Orders tab as needed

- Select the Assemblies to build and update Quantity (as needed)

- Press Submit.

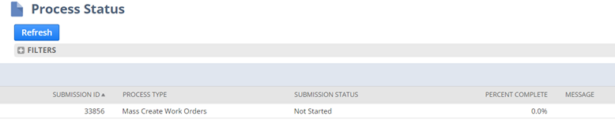

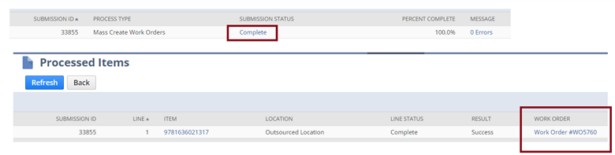

- Press the Refresh Button until Complete displays under the Submission Status column.

Once the status updates, click the Complete link to view the processed Work Order.

Options for Creating the Outsourced Purchase Order

Option 1: Directly from the Work Order (one PO at a time)

Option 2: Using the Outsourced Manufacturing Management screen (for bulk creation of POs)

Option 1:

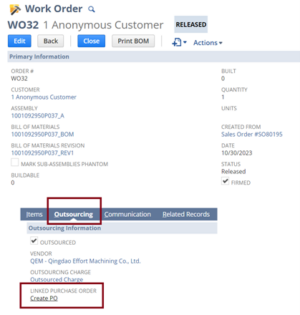

– Click the Create PO link under the Outsourcing tab of the Work Order.

– Press SAVE

Option 2:

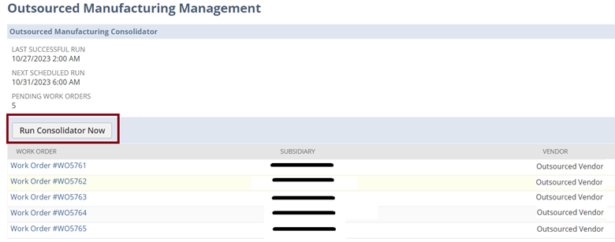

– Navigate to Setup > Manufacturing > Outsourced Manufacturing Management

– Any released Work Order with Outsourced = TRUE awaiting Purchase Order creation displays on this page.

– To automatically create Outsourced Purchase Order(s), press the Run Consolidator Now

– Work Orders with the same Outsourced Vendor will be consolidated into a single Outsourced Purchase Order.

– Navigate to one of the processed Work Orders to view the Outsourced Purchase Order(s).

– The Outsource Purchase Order references all the Work Orders listed on the Outsource Manufacturing Management screen prior to consolidation (provided the Work Orders reference the same Outsourced Vendor)

RSMUS.com

RSMUS.com