Whether you are pharmaceutical, biopharma, or medical device company and use a third-party contract manufacturing organization (CMO), this new NetSuite enhancement helps manage your commercialized assembly production process with your sub-contract vendors. This new feature helps you synchronize your procurement (Service for Purchase) and production transactions of your Assembly Items directly in NetSuite. No longer will the work order and assembly build process be separate from the third-party contract service that your vendors are providing. The service item, vendor purchase order, and item receipt are now connected to the work order and assembly build transaction.

How does this new enhancement help you?

This new feature will help align the Life Science processes below at different or same vendor locations within your NetSuite environment. Examples of these vendors and vendor locations could be Patheon, Novasep, Cardinal Health, Catalent, Almac, Knipper, Flextronics, AmerisourceBergen (ICS), PCI, Steris, Cipan, Carbogen, etc.

Helps to directly align Assembly/BOM process to your vendor’s PO service task:

- Active Pharmaceutical Ingredient (API) creation from components and the associated API Production Service for Purchase Item of the tasks being requested

- Drug Substance (DS) creation from API components and the associated DS Production Service for Purchase Item of the tasks being requested

- Drug Product (DP) creation from DS components and the associated DP Production Service for Purchase Item of the tasks being requested

- Finished Good (Tablets, vials, etc.) creation from DS components with packaging and the associated Packaging Service for Purchase Item of the tasks being requested

- Non-sterilized Item creation from components and the associated Production Service for Purchase Item of the tasks being requested

- Sterilized Item creation from components or non-sterilized items and the associated Sterilization Service for Purchase Item of the tasks being requested

- Drug Sample Item creation from DP or Finished Good items and the associated Sample Production Service for Purchase Item of the tasks being requested

- Medical Device Finish Good creation from DS or DP with non-drug components and associated Medical Device Production Service for Purchase Item of the tasks being requested

Outsourced Manufacturing NetSuite Setup Criteria: What do you need to set this feature up?

You must enable the features below:

- Multi-location Inventory

- Assembly Items

- Work Orders

- Purchase Orders

- Advanced Receiving

- Advanced Bill of Materials

You must create the elements below:

- Define cost categories for outsourcing charges

- Define Other Charge for Purchase or Service For Purchase Items

- Create Bill of Material (BOM) Revisions for each Assembly Item for each step of your contract manufacturing process

- Identify Vendors to be Outsourced Manufactures at a particular location on their vendor records

- Customers can outsource either by using a Standard Outsourced Purchase Order or from a Work Order

*Note: Manufacturing Work in Process feature must not be enabled.*

See how this new feature works and connect all transactions

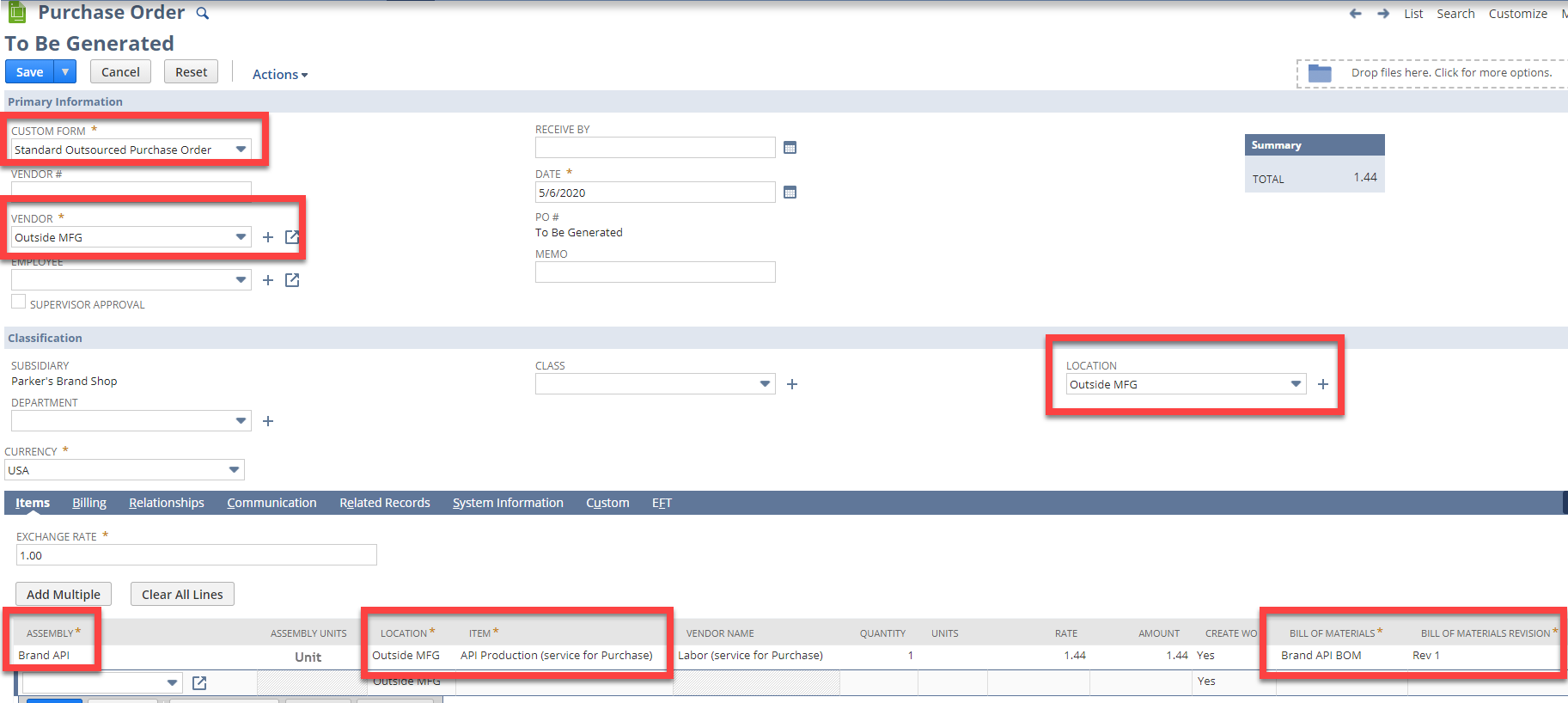

Create Outsourced Purchase Order for API creation:

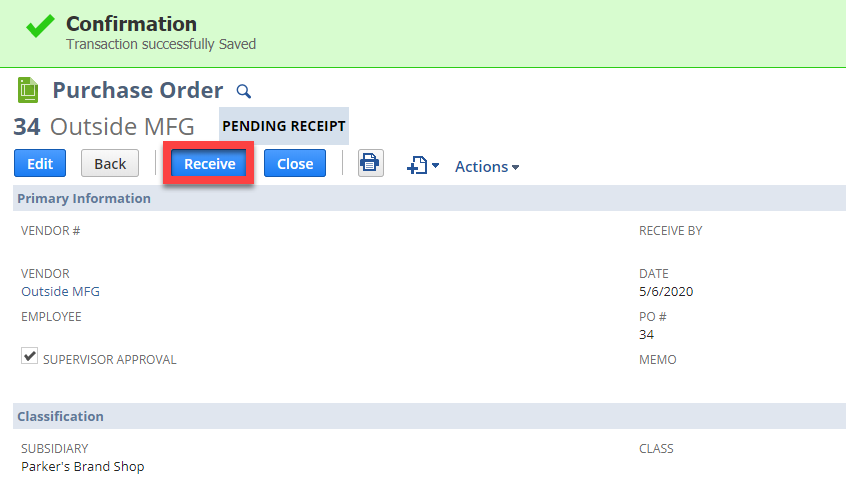

Click Receive Outsourced PO:

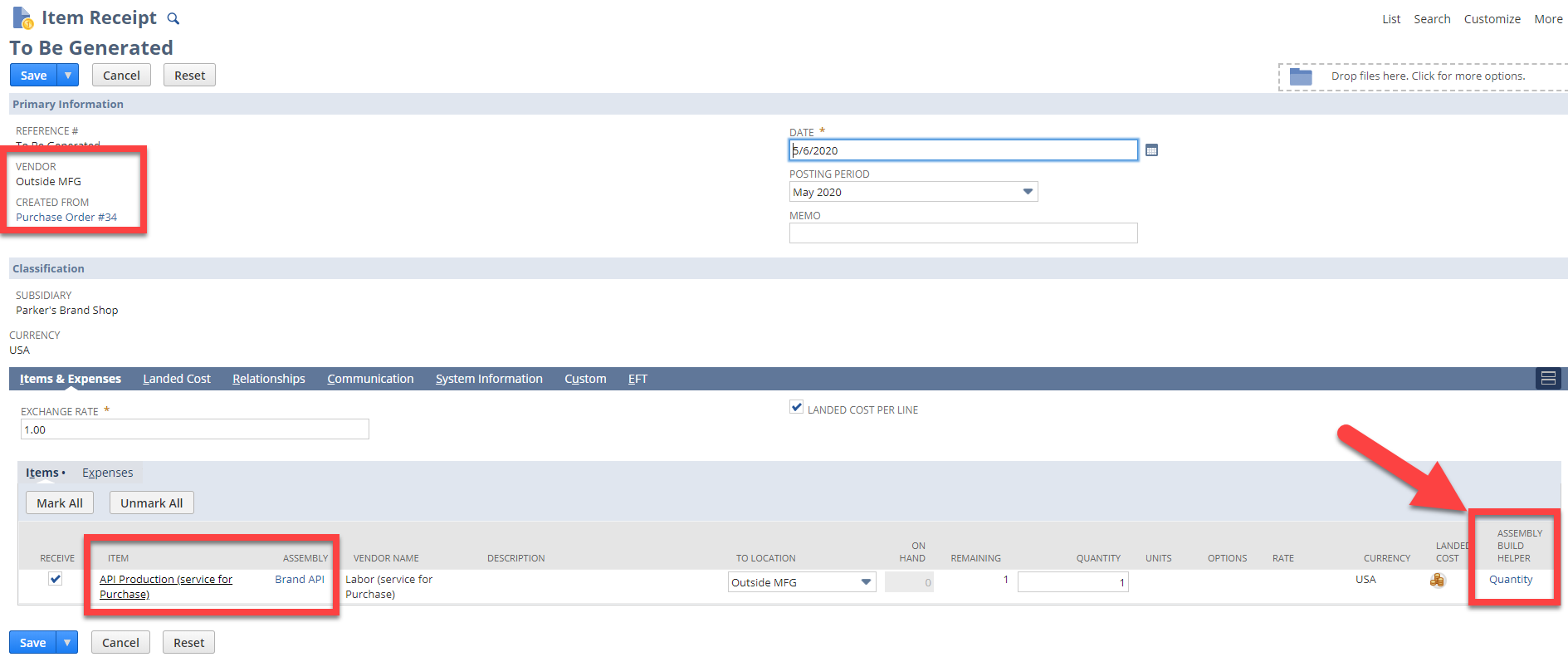

Once in the Item Receipt, click the Assembly Build Helper:

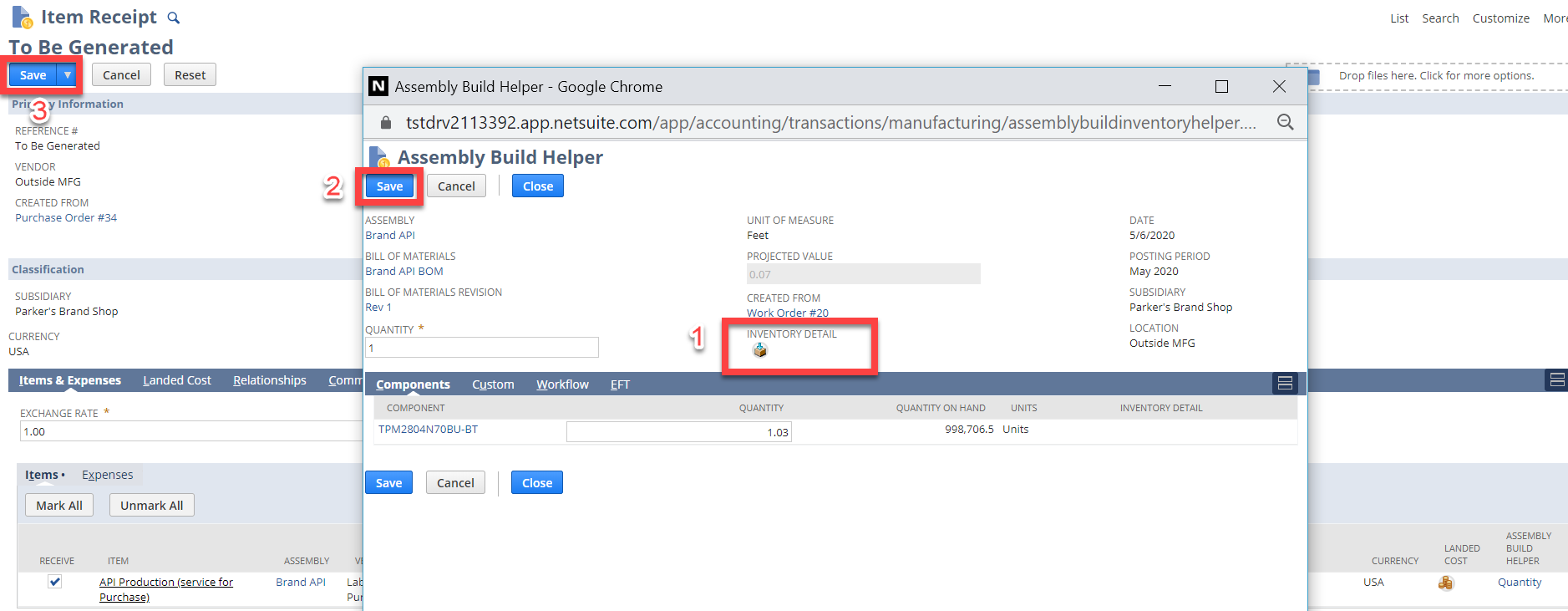

- Select the Inventory Detail on the component line and/or header.

- Then click Save in Assembly Helper.

- Lastly, click Save in Item Receipt.

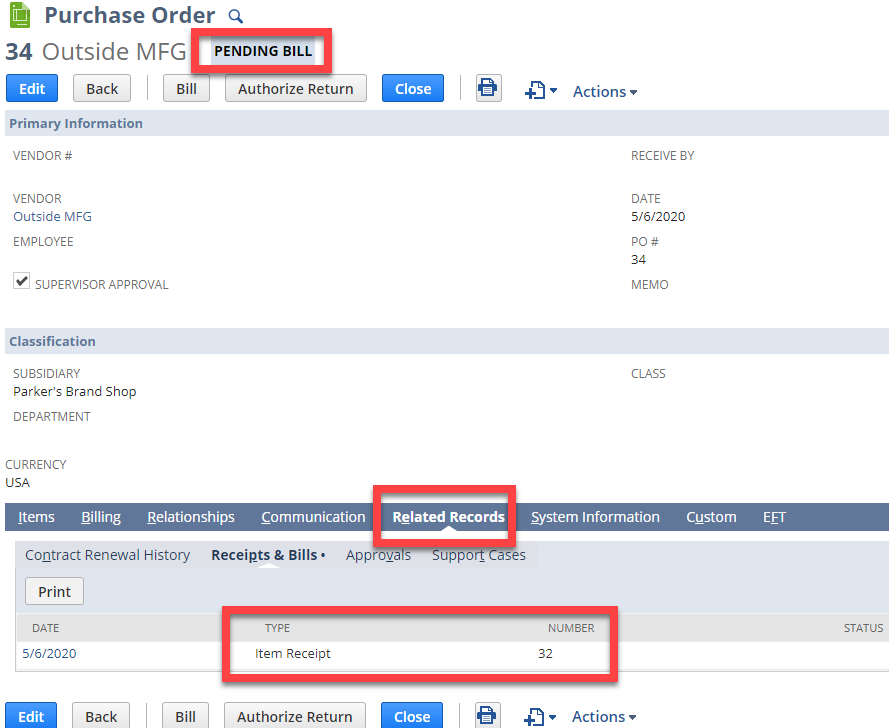

Now the outsourced PO is Pending Billing and connected to the PO Receipt of the Service for Purchase.

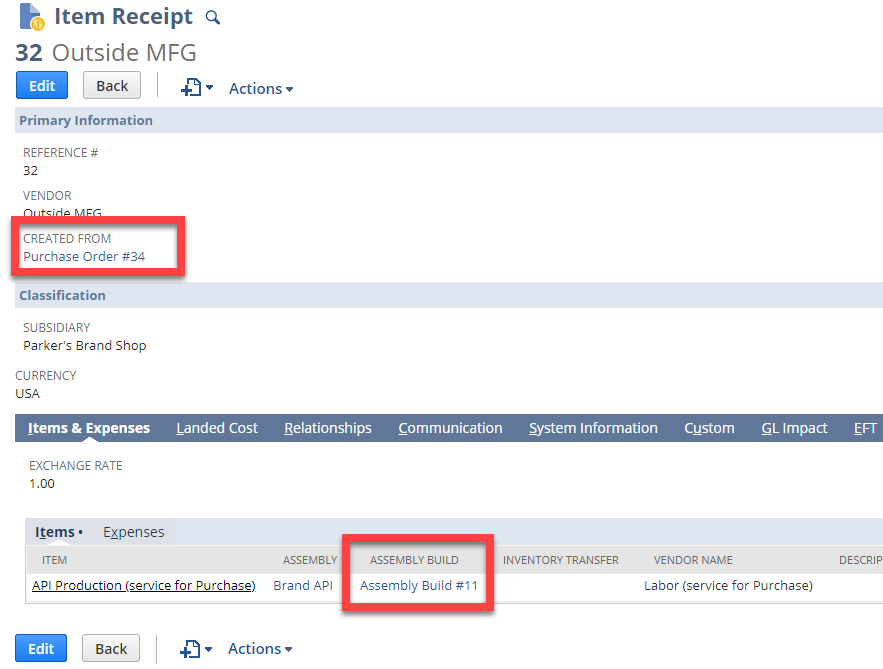

And the PO Receipt is connected to the Assembly Build transaction that created the Brand API.

If you would like more information on this topic or others related to NetSuite, please reach out to RSM’s NetSuite professionals by contacting us at NetSuite@rsmus.com.

RSMUS.com

RSMUS.com