Introduction

The Food and Beverage industry is challenged with producing safe, high-quality products at the lowest cost while following strict regulatory requirements. Since their products are for human consumption, any deviation in the production process can cause contamination leading to illness, disease, or death. Keeping equipment running is a big part of maintaining a consistent, safe process.

Machine breakdowns can cause significant unplanned downtime. This downtime can cost an organization thousands, or possibly hundreds of thousands, of dollars per hour, and the cost of breaking safety and regulatory requirements is immeasurable. Having a maintenance plan is key to keeping your equipment running efficiently and safely.

There are several different strategies for equipment maintenance. We will cover the more traditional maintenance strategies, reactive and preventative maintenance.

Reactive Maintenance

Reactive maintenance is a strategy that focuses on fixing your equipment after it has already failed. As an organization, you are constantly responding to equipment repairs and subsequently incurring expensive and unsafe downtime. First, reactive maintenance leads to increased maintenance costs and a shorter lifespan of equipment, and second, reactive maintenance is very unstructured and does not accommodate federal regulations.

Though reactive maintenance is not a recommended strategy for the food and beverage industry, there will always be some form of reactive maintenance since equipment will break down at some point. The goal should be to implement a proactive strategy that will limit the frequency of your equipment breakdowns.

Preventative Maintenance

To keep costs down and productivity up, most organizations in the food and beverage industry use a preventative maintenance approach with their equipment. Based on time or event triggers, and knowledge from the manufacturer of the equipment, equipment is cleaned, and parts are replaced to prevent unexpected breakdowns. Before parts begin to fail, they are replaced or repaired based on knowledge that they will fail and the frequency at which they do. This is done during planned downtime of the equipment at regular intervals.

In addition, many organizations are using sensors to help with their preventative maintenance strategy. Sensors can monitor things like temperature, run time, and fluid levels, all of which allow an organization to monitor their equipment 24/7 and prevent damage to critical systems. Over the years, the cost of sensors has come down and made them more accessible. Sensor data can make diagnosing a potential problem easier and reduces downtime caused by inspections of the equipment, all of which makes preventative maintenance effective.

Creating a Preventive Maintenance Strategy

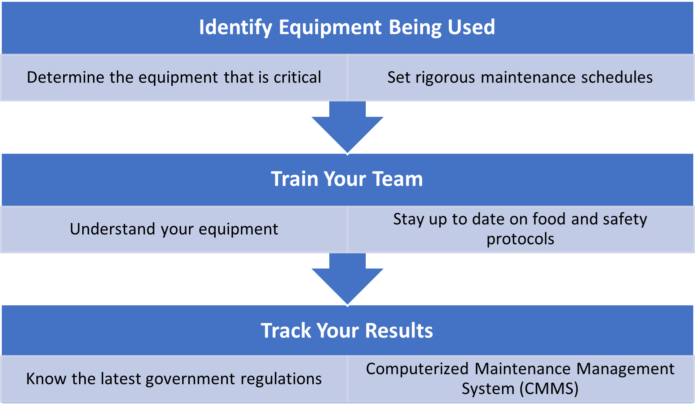

The first step to having a good preventative maintenance strategy in the food and beverage industry is to identify all the equipment being used. Identify the assets being used in the manufacturing process but don’t forget to include things like storage systems, equipment used to move the product before, during, and after the production process, and even the environmental equipment like the HVAC system. Any breakdown can cause contamination and safety concerns for the product being produced. Identify which pieces of equipment are more critical and which are most likely to cause significant downtime. Set a more rigorous schedule to the preventative maintenance schedule of those machines, being sure to take the age of the equipment into consideration. Older equipment will tend to break down quicker and may need more frequent safety inspections and replacement parts.

Next, make sure that your maintenance personnel have what they need to be efficient. Get the proper training for them, not only regarding the equipment that they will be maintaining, but with regards to operational and food safety. If your maintenance team doesn’t understand the importance of food safety protocols, there may be contaminants or quality control issues introduced to the production process. Preventative maintenance is less effective if equipment isn’t properly cleaned after it is inspected or repaired.

Tracking the results of your preventative maintenance strategy is also an important step. If there are breakdowns to equipment more frequently than expected, adjust your maintenance schedule to prevent these failures. Also consider that federal food and beverage regulations change and must be accounted for. Your preventative maintenance plan should be continuously improving based on what is happening on the production floor and the regulations imposed on your organization.

CMMS Software

Preventative maintenance plays a special role in the food and beverage industry. Besides being more productive and having less downtime, regulatory compliance is critical. To be compliant, records must be kept tracking your maintenance. Some organizations still use a pen-and-paper system with spreadsheets to manage and track maintenance. But with spreadsheets being easily manipulated and having little security as to who can access them, it is not a reliable system. The use of a CMMS should be considered. A CMMS (Computerized Maintenance Management System) can help prepare and track maintenance tasks and make it easy to provide compliance documentation. A CMMS can also be used to create and manage work orders to perform preventative maintenance. In the food and beverage industry, preventative maintenance makes CMMS a requirement.

Be sure to check out the next blog in our maintenance series where we explain predictive and prescriptive maintenance and the role these strategies play in the food and beverage industry.

RSMUS.com

RSMUS.com