This blog is co-authored by Nikita Kumari and Brittany Quinlan.

Effective quality management helps organizations meet regulatory and internal quality expectations. This can help formalize and assess the company’s inventory and process standards. The NetSuite Quality Management SuiteApp helps provide templates and tools to help you maintain and associate quality data to other business records and workflows to spot issues, such as a new vendor not meeting expectations.

Let us look at NetSuite Quality management, its benefits, features, applications, and the major enhancements to the Quality Management SuiteApp.

NetSuite can automate your quality management processes and standards to allow your business to deliver high-quality products.

What is NetSuite Quality Management?

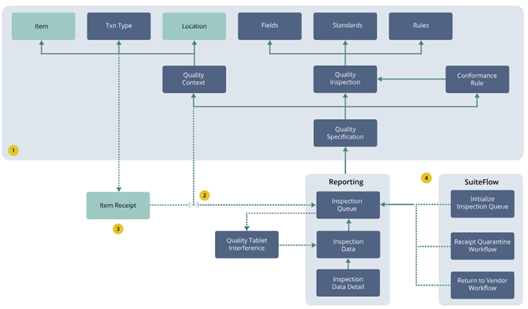

NetSuite Quality Management formalizes and automates policies, standards, and practices to deliver the highest quality products with minimal overhead. With NetSuite QM (Quality Management), one can quickly and easily select the tests they want to perform, parameters can be set to evaluate results, and policies can be defined for testing at the receiving stage and during the production process. With this, NetSuite automatically tells inspectors what to test and when; it also collects results and executes remediation workflows as required.

Quality management processes comprise inspection types, criteria, parameters, and failure procedures. Your program can be customized to your business’s specific requirements. As processes change, existing inspections and specifications can be updated, and new processes can be created in the Quality Management SuiteApp.

Quality Process Flow:

Why Choose NetSuite Quality Management?

Automation can help your business achieve consistent quality and increased customer satisfaction with a streamlined quality management system. NetSuite Quality Management minimizes rework and reduces costs by identifying problems before manufacturing is complete, enabling you to tackle manufacturing inefficiencies proactively. Discover pain points and identify issues with NetSuite’s templates and tools that can help your business maintain and organize data. With real-time test monitoring and access to outcomes, your entire process can be inspected to maintain internal and external standards.

NetSuite Quality Management Benefits:

Formalized Quality Policies, Standards and Practices: NetSuite QM ensures quality inspections are performed consistently based on applicable metrics. Quality engineers can inspect, review standards, record results, and submit data for analysis.

Improved Product Quality: Regular inspections ensure products meet customer expectations before entering into inventory. The quality inspections can be triggered automatically based on select actions or conditions. This ensures that products and materials are checked consistently, regardless of who is performing the inspection.

Easy Collection of Inspection Results: Using the mobile app, the users can automatically collect and record inspection results and set prompts for the next steps when necessary.

Analysis of Large Volumes of Raw Data: With the large volume of raw data present, the users can define how many items need to be inspected and the rules of these inspections, then the data can be gathered and analyzed right in NetSuite.

NetSuite Quality Management Features:

Test Definitions: NetSuite provides a master list of predefined profiles that specify the inspection type to perform and acceptable limits. It also specifies the inspector and the category’s minimum qualifications and inspection method. With this, businesses can enforce standards on inspector credentials, capture measurements, and compare data to pass/fail limits. Multiple data elements can be used to set up each inspection that defines the inspection process’s parameters.

Receiving and In-Process Inspection: Tests associated with a particular item can be performed on demand, upon receipt, and during manufacturing. Because tests have already been defined, they are easily attached to an item or operation to ensure compliance with quality-control procedures. Items that fail an inspection can be moved to a hold location for further processing.

Mobile Data Collection: NetSuite’s tablet interface provides a convenient way to capture and process test data directly from the shop floor or receiving dock. The mobile collection interface is designed to deliver all the information a quality engineer needs to gather and analyze results efficiently and accurately. With the tablet, engineers can easily perform inspections, review standards, record outcomes, and submit data for analysis directly from the work area — providing real-time feedback and instant access to testing outcomes.

Challenges NetSuite Quality Management Solves:

High Cost of Goods Sold (COGS): Many businesses face the challenge of the High Cost of goods sold. NetSuite QM helps lower the cost of goods sold by minimizing reworks and defects in the product.

Vendors Not Meeting Standards: Vendors often cannot meet the standards. The QM system helps inspect raw materials and conduct spot checks throughout production to ensure the standards are met.

Unsatisfied Customers: Increased returns and client dissatisfaction can create a scenario of unhappy customers. NetSuite QM system can be used to minimize returns and increase client satisfaction by delivering products that meet expectations.

Quality Disparities: A quality management system solves the quality disparities. It eliminates inconsistency by ensuring products are produced according to preset parameters.

NetSuite 2023.2 Enhancements

NetSuite Quality Management SuiteApp has always been a powerful support. With the latest release, you can do a few more things.

NetSuite 2023.2 includes the following enhancements to the Quality Management SuiteApp:

NetSuite 2023.2 includes the following enhancements to the Quality Management SuiteApp:

- Automatically Assign the Quality Management Inspection Queue

- Support Quality Management Tablet Navigation from SCM Mobile Framework

- Generate COA (Certificate of Analysis) for Item Fulfillment from a Transfer Order

- Quality Management Improvements and Fixes

Automatically Assign the Quality Management Inspection Queue

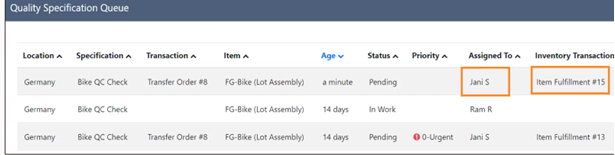

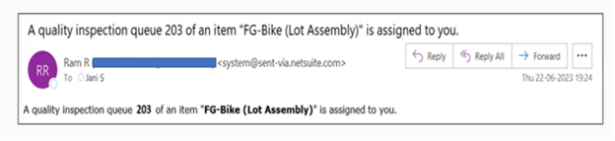

The NetSuite 2023.2 Quality Management SuiteApp enables you to assign an employee while creating an inspection automatically. After the employee is assigned, the Quality Management SuiteApp sends an email notification to that employee when an inspection queue is created and assigned.

Setup: User can specify the employee to a Transaction in the Quality Specification Context

Setup: User can specify the employee to a Transaction in the Quality Specification Context

After the inspection queue is generated, email alerts are sent to the assigned employee. The corresponding employee can be notified immediately once an item is ready for inspection.

Support Quality Management Tablet Navigation from SCM Mobile Framework

The NetSuite 2023.2 Quality Management SuiteApp also now supports Quality management tablet navigation from the SCM Mobile Framework. It enables you to share a link from an SCM Framework application that will open the Quality Management application on a mobile tablet. This includes such products as the Manufacturing Mobile SuiteApp, WMS, Ship Central, and Smart Count, to name a few.

SCM Mobile Suite Apps – Quick navigation to QM.

Now, you can work and monitor Quality management from afar. Navigate to Mobile Apps: Setup > Custom > Mobile – App

Generate COA for Item Fulfillment from a Transfer Order

The NetSuite 2023.2 Quality Management SuiteApp enables you to use Transfer Orders to generate a Certificate of Analysis (COA) for Item Fulfillment. Now, you can generate a certificate of analysis for item fulfillment once you receive a transfer order.

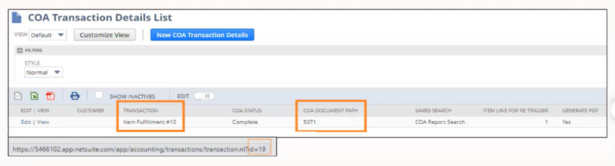

On fulfillment of the Transfer Order, the system generates the COA.

Navigate to Customization > Lists, Records and Fields > Record Type.

Click List for Record type: COA Transaction Details.

Hover the mouse on Transaction to identify the folder name where the COA document is generated.

Quality Management Improvements and Fixes

The NetSuite 2023.2 Quality Management SuiteApp includes the following improvements and fixes:

- When you use the Advanced Manufacturing tablet to make production inventory reports, you can now generate an inspection queue without creating duplicate lots or serial numbers.

- An inspection queue with the correct transaction quantity can now be created for a partial Item Receipt and a partial Item Fulfillment Transaction.

- The Quality Management SuiteApp enables you to change the inventory status as part of the Enhanced Receipt Quarantine Workflow without initiating a bin transfer.

- You can use the ad-hoc process to generate an inspection queue with the correct transaction line number.

- The Quality Management SuiteApp displays the full quantity in Certificate of Analysis (COA) documents.

- You can now set a default saved search using Tablet view.

- Quality Management lets you display assignee and priority values in the inspection queue details.

Conclusion

NetSuite can automate your quality management processes and standards to allow your business to deliver high-quality products. NetSuite Quality Management gives businesses visibility and control to achieve consistent quality with minimal overhead. Predefined profiles that specify inspection types and methods, acceptable limits, and inspector qualification requirements are provided to capture and compare data. Test definitions accommodate the usage of multiple data elements in inspection processes. Another feature of NetSuite Quality Management is the ability to perform receiving and in-process inspections. Use predefined test definitions attached to items or operations for compliance verification. NetSuite also provides mobile capabilities, making it easy to perform inspections, review standards, and submit data directly from the inspection area with a mobile device for real-time feedback and access to results.

RSM’s experienced NetSuite team can provide more information on how this solution can work for your business. Reach out to our NetSuite professionals to learn more!

To reach out to our team please contact us here.

RSMUS.com

RSMUS.com